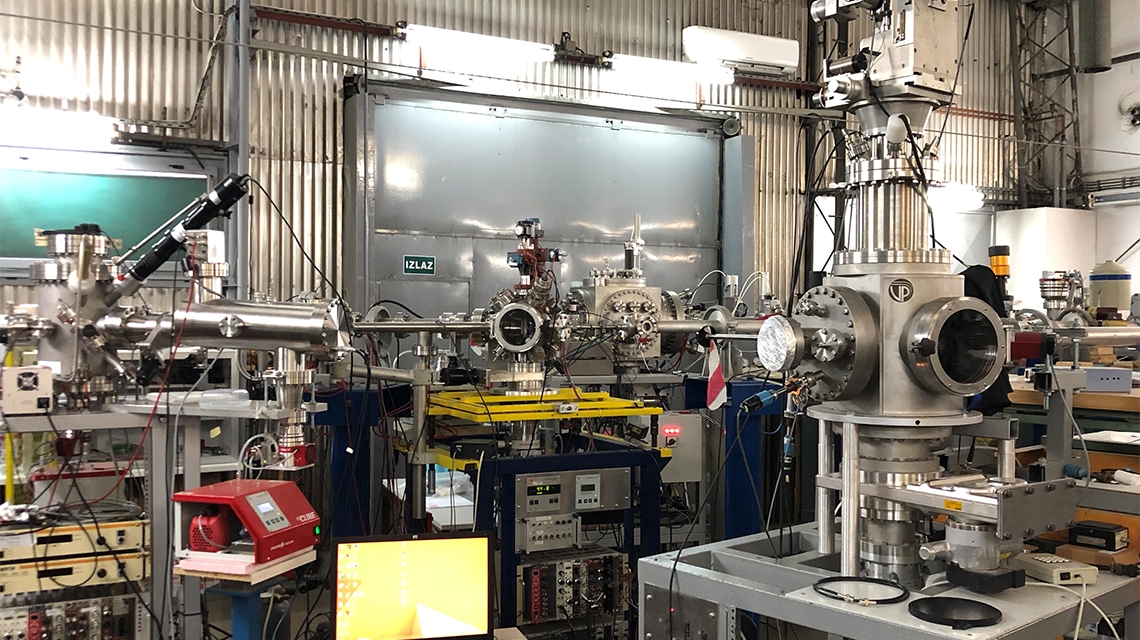

The most challenging science and engineering endeavour on earth is arguably fusion. Building a fusion reactor, achieving a self-sustaining reaction and converting that power to near inexhaustible electricity will change humanity and our relationship with energy forever. As enticing as this may sound, progress has not been easy or smooth. Technical challenges around the structures, fuels and materials needed to hold such complex machines together remain only partially solved.

Understanding the technical limits and gaps of knowledge faced by fusion energy today begins by looking inside the reactor itself.

Inside a tokamak reactor, a super-hot ionized gas or ‘plasma’ is heated to over 100 million degrees Celsius (°C) to induce fusion reactions. Confined by powerful magnetic fields, the walls of the reactor are protected from the volatile plasma.

Plasma used in nuclear fusion is usually made up of two heavy isotopes of hydrogen — deuterium and tritium — which then fuse to produce helium and neutrons. In fusion power plants, engineers hope to ‘breed’ or create additional tritium from the reaction itself with yet untested lithium blanket shielding that reacts neutrons resulting from fusion.

“The energy of the fusion-generated neutrons poses serious challenges to the fusion power plant’s first wall and vacuum vessel, which means considerations need to be given to radiation damage, biological shielding, remote handling, and safety,” explained Ian Chapman, CEO of the United Kingdom Atomic Energy Authority.

Chief among engineers’ tasks is developing high-performance materials that are able to sustain high temperatures and the intense neutron fluxes from the reaction. Understanding the impact of operating conditions on the plasma-facing components is also essential for the future of large-scale fusion power plants.